rock well hardness test pdf|iso 6508 1 2023 pdf : supermarket NISTRecommendedPracticeGuide SpecialPublication960-5 RockwellHardness Measurementof MetallicMaterials U.S.DepartmentofCommerce DonaldL.Evans,Secretary . MINAS DIA - MG, 15h - Resultado do dia 24/02/2024 (Sábad.

{plog:ftitle_list}

Rafaela nery (@rafaelanery.com) no TikTok |1.4M curtidas.143.3K seguidores.20 anos Ig @rafaelanerylucca 🔎 Rafaelanery.com🥰.Assista ao último vídeo de Rafaela nery .

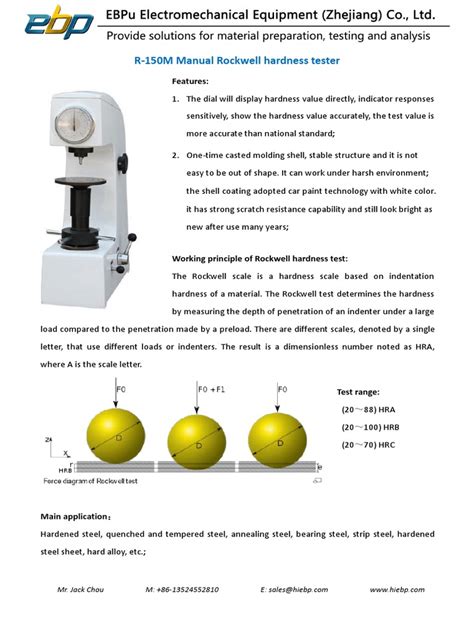

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. .

Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In . NISTRecommendedPracticeGuide SpecialPublication960-5 RockwellHardness Measurementof MetallicMaterials U.S.DepartmentofCommerce DonaldL.Evans,Secretary .This document specifies the method for Rockwell regular and Rockwell superficial hardness tests for scales A, B, C, D, E, F, G, H, K, 15N, 30N, 45N, 15T, 30T, and 45T for metallic materials .

rockwell hardness testing procedure pdf

Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators and the methods used are following proper test technique and practice. The precise nature and .

This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic .The Rockwell hardness of a material is a measure of its ability to resist permanent deformation when in contact with an indenter under load. Hardness measurements can aid.

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

rockwell hardness testing guide pdf

*Dedicated to the Rockwell Superficial hardness test V-anvil (small) 810-041 (Outside ø40 mm, Groove width 6 mm) For shaft materials (max. ø8.4 mm) Spot anvil 810-044 (Outside ø5.5 mm) For sheet specimens Digimatic mini-processor DP-1VA LOGGER 264-505A Connection cable not supplied. (To be ordered separately.)

additional test force (permanent indentation depth) mm HRA HRC HRD Rockwell regular hardness =100 0 002 − h, HRBW HREW HRFW HRGW HRHW HRKW Rockwell regular hardness =130 0 002 − h, HRN HRTW Rockwell superficial hardness =100 0 001 − h, 5 Rockwell hardness 5.1 The following is an example of the designation of Rockwell .3.1 Macro Hardness Test Methods 3.1.1 Rockwell Hardness Test The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load 𝐹0 (Fig. 1A) usually 10 kgf. When equilibrium has been reached, anISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two force levels using the specific conditions defined in Clause 7. The specified preliminary force is applied The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

rockwell hardness test calculation

PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on ResearchGate 3.1.5 Rockwell super cial hardness test same as the Rock-well hardness test except that smaller preliminary and total test forces are used with a shorter depth scale. 3.1.6 Rockwell hardness number a number derived from the net increase in the depth of indentation as the force on an indenter is increased from a speciÞed preliminary test force to

3.1.5 Rockwell superficial hardness test—same as the Rock-well hardness test except that smaller preliminary and total test forces are used with a shorter depth scale. 3.1.6 Rockwell hardness number—a number derived from the net increase in the depth of indentation as the force on an indenter is increased from a specified preliminary test .5.1.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

the Rockwell hardness test ( scales and hardness range according to Table 1) for metallic materials. NOTE — For certain materials, the hardness range may be narrower than those indicated. 2 REFERENCE The following Indian Standard contains provisions which through reference in this text, constitutesRockwell Hardness Test formula. Your testing equipment will provide an accurate calculation of the Rockwell hardness result, but there’s a formula to calculate the depth that’s measured into a Rockwell hardness number, which is: HR=N-(d/s) Where the value of: d is the penetration depth measured from point zero in mm s is either 0.001 mm or . Rockwell hardness test - Download as a PDF or view online for free. . AI-enhanced description. yash patel Follow. The Rockwell hardness test was invented in 1914 by Hugh and Stanley Rockwell. It measures the .Rockwell hardness test is to apply diamond cone indenter (see Fig-2) or steel ball indenter (see Fig-3) to the specimen surface in two steps as shown in Fig-1, which shall be retained for a certain period of time, and measure the residual indentation depth under preliminary test force after the main test force is removed. The Rockwell hardness is

The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to “good practice” procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement .The document describes the Rockwell hardness test. It discusses the theory behind hardness and introduces the Rockwell hardness tester. The tester uses different combinations of loads and indenters to test a wide range of materials. An experiment is described where steel and brass samples are tested using the Rockwell hardness scale. The hardness values obtained from .obtained from computer-generated curves of actual test data. Most Rockwell hardness numbers are presented to the nearest 0.1 or 0.5 hardness number to permit accurate reproduction of these curves. Since all converted hardness values must be considered approximate, however, all converted Rockwell .ISO 3738-1, Hardmetals — Rockwell hardness test (scale A) — Part 1: Test method [2] ISO 4498, Sintered metal materials, excluding hardmetals — Determination of apparent hardness and microhardness [3] ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995) [4]

rockwell hardness scale pdf

Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. This could have detrimental and catastrophic effects on the performance and the integrity of the goods they are used in. Rockwell Test Techniques4.3 Verification of the indenter 4.3.1 Diamond cone indenter (scales A, C, D, N) To verify the reliable performance of the conical indenter in conformance with this part of ISO 6508, a direct

Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters 1 Scope This document specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508-1, together with a method for verifying

12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load.Ans: a) in Vickers hardness test we apply loads vary between 5-120kgf. And in Brinell we apply between 500 – 3000 kgf. And in Rockwell hardness test we apply two loads, first is the initial load then the major load. b) in Vickers hardness test we use diamond pyramid with (136°) apex angle as an indenter. And in Brinell Hardness Test we use spherical 5 or 10 mm diameter .Metallic materials — Rockwell hardness test — Part 1: Test method. Edition 4 2016-08. Withdrawn. ISO 6508-1:2016. 70460. ISO 6508-1:2016 Metallic materials — Rockwell hardness test Part 1: Test method. Withdrawn (Edition 4, 2016) .

The Rockwell hardness test is often used as a ‘quick test’ on the production floor or in the laboratory, mainly for metallic materials. However, it can also be used for more advanced tests, such as the Jominy test (End Quench Test). Due to the relatively high loads used, application of the Rockwell hardness test is generally limited to .

iso 6508 1 2023 pdf

hardness tester lab report pdf

Resultado da Signals Blue. 123 419 subscribers. We are the provider of high-quality crypto signals. The services we provide are based on knowledge and experience. What is more, the signals we give are always analyzed and consulted before with specialists and professionals from around. @SignalsBlueAdmin. View .

rock well hardness test pdf|iso 6508 1 2023 pdf